The Product Detection Controller (PDC) is designed to detect a fault due to the

absence of a required feature such as a label, insert, cut-out, glue, printing, cap,

etc. When a fault is detected, a "Machine Stop" signal is activated. This can be configured to stop the equipment and/or notify the operator of a fault condition.

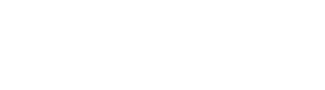

Using the input from two sensors the PDC can detect virtually any product

feature. Sensor #1 is the "Trigger" sensor which detects the product carrier:

box, label, bottle, etc. Sensor #2 is the "Product" sensor which detects the

feature of interest: label, insert, glue, cap, etc.